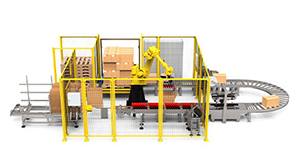

ROBOTIC CASE PACKER AND PALLETIZER FOR STAND-UP POUCHES

The TT-1400RELP is a Robotic Top Load Case Packer and Palletizer that can reach speeds up to 2 cases per minute. The robotic arm with specific EOAT is utilized for case erecting, case loading, and palletizing applications, which makes this solution ideal for a business that values flexibility and compactness over speed. Designed and built for case packing of stand-up pouches, this particular model is perfect for the casing of any pouch-packed product, whether it’s coffee, flour, sugar, candy, or stick packs.

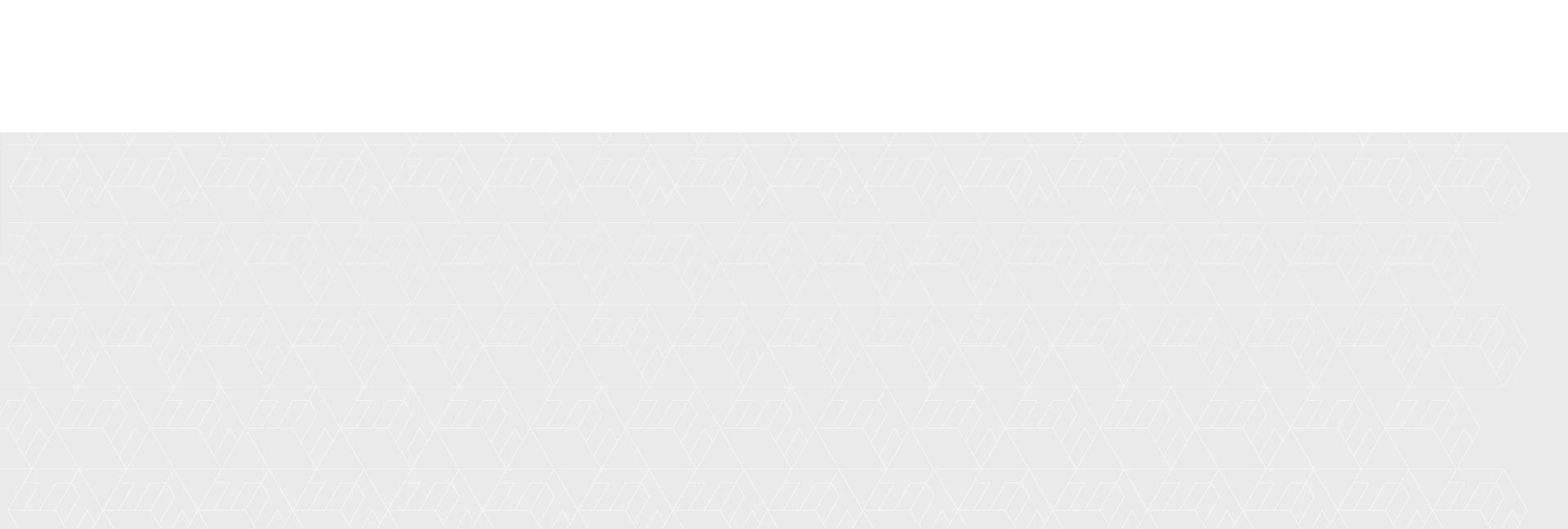

PRODUCT CASE PACKING PROCESS

PRODUCT CASE PACKING VIDEO

TECHNICAL

SPECIFICATION

| TYPE | Robotic Top Load Case Packer and Palletizer /td> |

| SPEED | Up to 2 CPM |

| CASE LOADING | Robotic pick-and-place system |

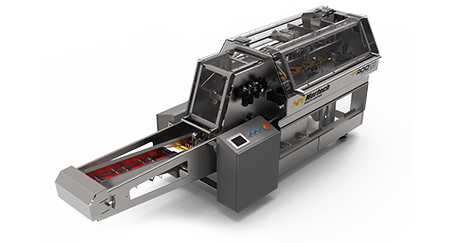

| PRODUCT COLLATION | Race Track Collation System |

| CASE CLOSING | Tape Closing System |

| CONTROLS | Allen Bradley PLC/Drive |

| SAFETY | Light Curtain |

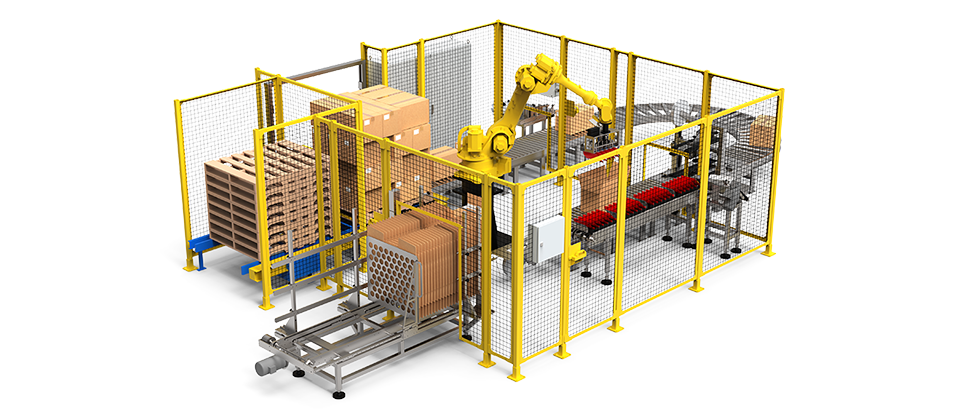

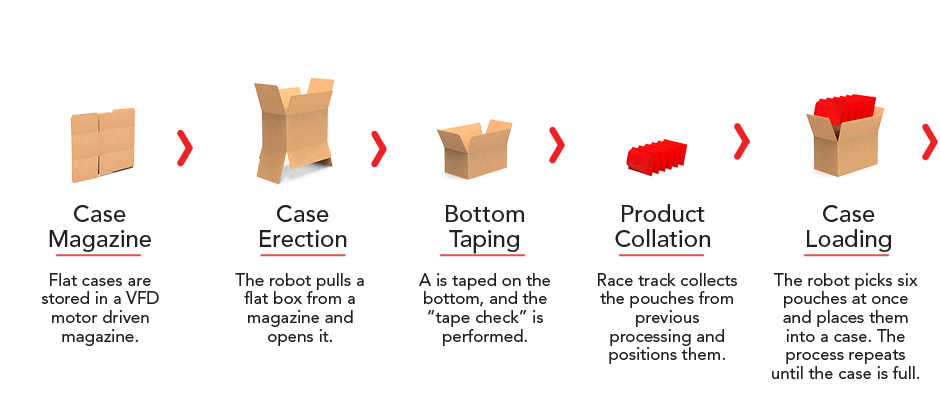

TT-1400RELP SEQUENCE OF OPERATIONS

A servo motor driven race track collects the pouches from previous processing and positions them for a robot pick and place operation. While the pouches are being prepared for the pick and place operation, Robot performs a box set up. A flat box is pulled from a VFD motor-driven magazine, opened, taped on the bottom, and after a successful “tape check,” it is positioned in front of the pouch pick and place station. When the box is full, it exits the robot fence guarded area and continues down the line to a top box sealer. Once the box passes the top case sealer, it will pass the sensors to ensure that the tape operation was successful. The box turns 180 degrees and is presented to a labeler. After a label is applied, the box enters the robot fence area to an accumulation section of the conveyor. In this area, the boxes are positioned in a robot palletizing position. The Robot lifts the box and places the box on the palletizing conveyor. The operator loads a pallet to a VFD motor-driven palletizing conveyor. The pallet is moved to the Robot palletizing position. Once completed, the pallet exits the Robot guarded area through a light curtain. The curtain’s function is to ensure that no one can accidentally enter the robot fence guarded area. Once the pallet is at rest, a forklift unloads the pallet from the conveyor.

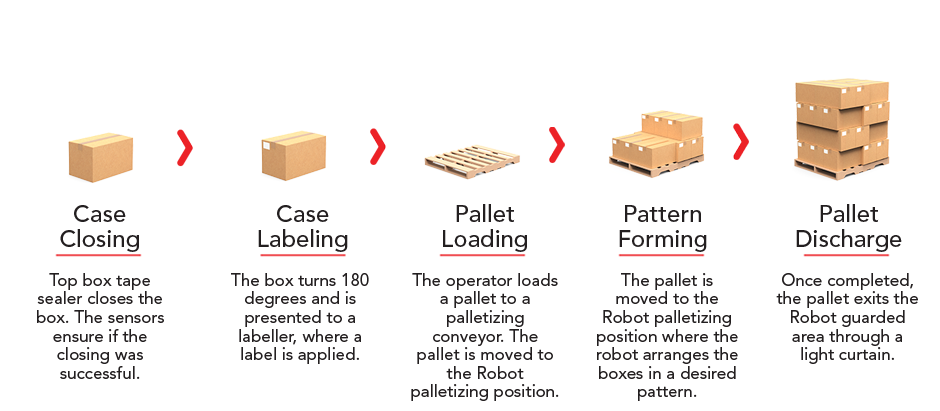

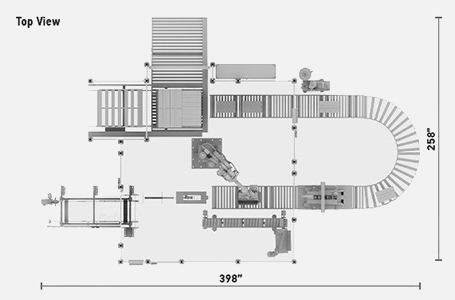

DIMENSIONS & FLOOR PLAN

TT-1400RELP features a compact overall footprint so you can rest assured it will fit your floor space.

Reliable and portable with simple operation and user-friendly interface, TT-1400RELP will be up and running in no time.

Built from welded tubular stainless steel with hinged cover panels and safety electrical interlocks, TT-1400RELP is a powerful and efficient case packer/ palletizer that meets the highest standards with state-of-the-art simplicity.

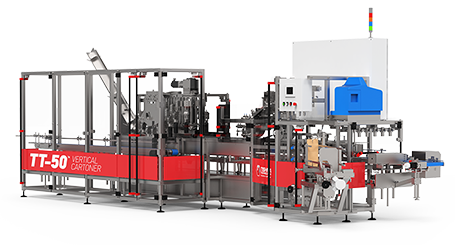

CAN BE INTEGRATED WITH